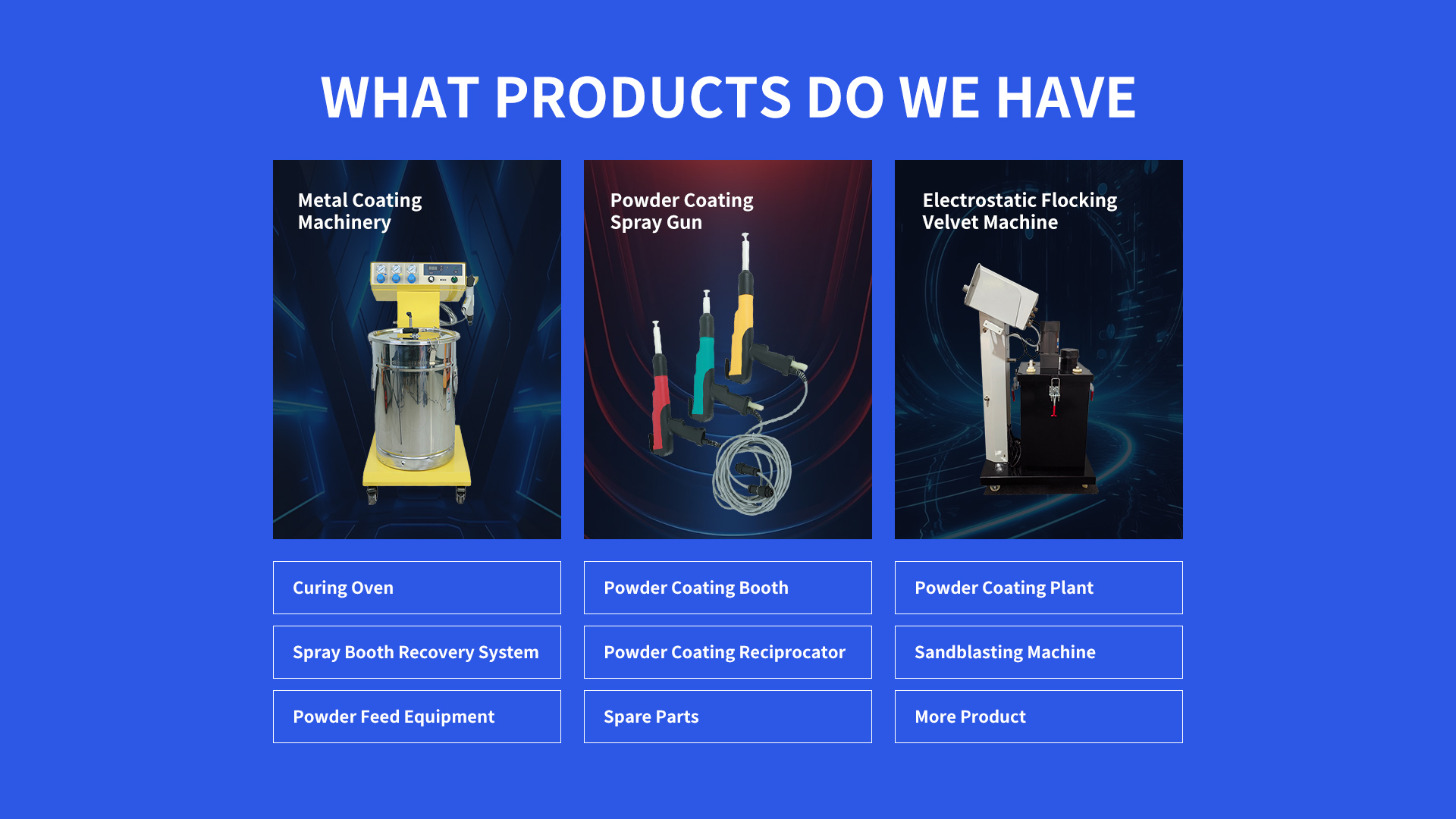

1. Introduction to Portable Powder Coating Machines

A Portable Powder Coating Machine is a compact, mobile system designed for applying dry powder coatings in diverse locations. Key components include a handheld electrostatic gun, lightweight powder hopper, rechargeable power unit, and compact curing tools. These machines prioritize mobility, making them ideal for on-site repairs, fieldwork, or small workshops needing flexible powder application solutions.

2. Applications of Portable Powder Coating Machines

Used in automotive repair, agricultural equipment maintenance, marine industries, and artistic metalwork. They coat items like trailers, fencing, machinery parts, and outdoor sculptures. Portable systems excel in on-site coating projects where transporting large parts to a factory is impractical.

3. Pricing of Portable Powder Coating Machines

Prices range from 2,000forbasicmanualkitsto25,000+ for advanced battery-operated systems with integrated curing. Mid-range models (5,000–15,000) offer features like extended battery life, adjustable voltage, and portable powder recovery capabilities.

4. Proper Use of Portable Powder Coating Machines

Clean surfaces thoroughly to remove rust or grease. Adjust the gun’s voltage (40–70 kV) and maintain a 6–10 inch spray distance. Use lightweight curing lamps or portable ovens for thermal setting (250–400°F). Clean the gun and hopper after each use to prevent clogs and ensure consistent portable coating quality.

5. Choosing a Portable Powder Coating Machine

Prioritize lightweight designs (under 30 lbs) for easy transport. Check battery runtime or power source compatibility (e.g., 110V/220V). Opt for models with quick-change powder containers and ergonomic grips. Ensure durability for rugged on-site environments.

6. Safety Precautions for Portable Powder Coating Machine Systems

Wear PPE (respirators, gloves) to avoid inhaling particles. Ground the workpiece and equipment to prevent electrostatic hazards. Operate in well-ventilated outdoor areas or use portable exhaust systems. Avoid using near flammable materials.

7. Design Advantages of Portable Powder Coating Machines

Compact, modular designs enable easy disassembly for transport. Battery-powered units eliminate reliance on fixed power sources. Advanced models feature powder recycling filters to reduce waste, while corrosion-resistant materials ensure longevity in harsh conditions.

8. FAQs About Portable Powder Coating Machines

Q: Can portable systems achieve factory-quality finishes?

A: Yes, with proper technique and portable curing tools, results rival stationary systems.

Q: How long does a battery last per charge?

A: Typically 4–8 hours, suitable for field coating tasks.

Q: Are they suitable for large parts?

A: Yes, but multiple passes may be needed for on-site large-scale coating.

Q: How to store powder in mobile setups?

A: Use sealed, moisture-proof containers to prevent portable powder clumping.

Q: Can they coat non-metals?

A: Limited to conductive materials unless using specialty primers.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com